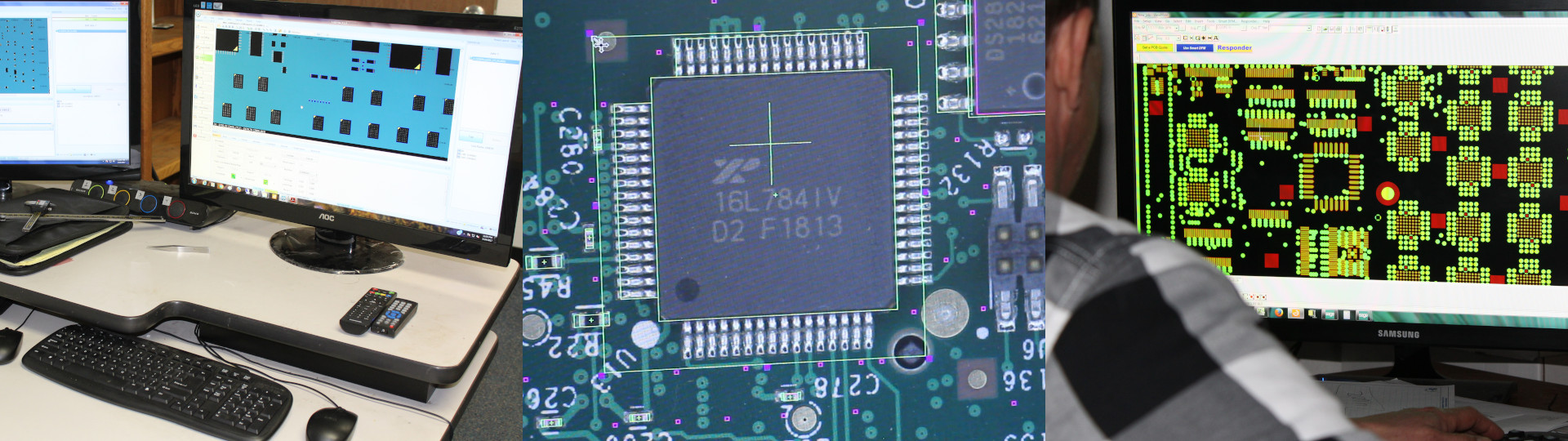

Surface Mount Technology/Printed Circuit Board Assembly

At NASO, we are committed to standardization in our SMT/PCBA process. By continually pursuing this goal, NASO has developed a highly repeatable SMT/PCBA process for complex assemblies. All SMT lines at NASO feature auto-loading smart feeder systems, 10MP Real-time vision inspection systems, and flying + stage vision systems.

Screen Printing

(4) EKRA SERIO 4000 screen printers

- Ekra Vision Alignment System

- 2 1/2D Inspection

- Closed-loop print head

- Gridlock engagement systems

Surface Mount Technology (SMT)

(4) Samsung SM481 pick and place machines

- 10 spindle head

- 38,000 CPH

- 10MP real-time inspection vision system

- Flying vision + Stage vision

- Auto-loading smart feeders

(2) Samsung DECAN F2 pick and place machines

- Dual heads with 10 spindles per head

- Dual rails

- 80,000 CPH

- 10MP real-time inspection vision system

- Flying vision + Stage vision

- Auto-loading smart feeders

(4) Samsung SM482 pick and place machines

- 6 spindle head

- 27,000 CPH

- 10MP real-time inspection vision system

- Flying vision + Stage vision

- Auto-loading smart feeders

(1) Samsung DECAN L2 pick and place machine

- Dual heads with 6 spindles per head

- Dual rails

- 56,000 CPH

- 10MP real-time inspection vision system

- Flying vision + Stage vision

- Auto-loading smart feeders

Reflow Ovens

(4) Heller 1701 MKIII reflow ovens

- Advanced flux management system

- Lead Free Certified

- Programmable Cooling

- Accurate to 0.1°C

(1) Heller 1809 EXL reflow oven

- Advanced flux management system

- Lead Free Certified

- Programmable Cooling

- Accurate to 0.1°C

Wave Solder

(1) E-Therm M400 Wave Solder

- Lead Free

- Full Titanium dual wave solder pot

- 2 individual hot air preheat zone

- Titanium finger conveyor

Automated Optical Inspection (AOI)

(3) Nordson Yestech FX Series Automated Optical Inspection

- 5 axis 3D NYT VISION Technology

- Advanced 2D + 3D inspection

- Multi-fringe digital projection

- High defect coverage/low false failure

- PC data collection & reporting

X-Ray

(2) Focul Spot 135 KVA Real-time X-Ray

Washing Machine

(1) Aquakleen T-15 DI washing system

- Closed loop

- High pressure SST pumps

- Drop-in immersion heaters

- Supercharged turbine blowers

- Data logging via OPC server